PROJECT WATER

Please enjoy these videos highlighting the construction of these two water treatment campuses and the Grand Opening event!

Thank You from all of us!

Time lapse of Airline/Lambert Site Construction

Grand Opening Zoom Recording

Time lapse of Picture Rocks Site Construction

Town Council approved Resolution No. 2018-091 on Tuesday, September 25 authorizing the creation of the Picture Rocks water treatment campus and the Airline/Lambert water treatment campus capital projects. Below are project updates, and more can be found on our Instagram page @MaranaWater.

RESIDENTIAL SERVICES SEARCH

Learn who provides water/wastewater to your address

Use the search bar below to determine which water provider serves your home. When searching for an address be sure to include the directional (N, S, E, W), for example 11555 W. Civic Center Dr, not 11555 Civic Center Dr.

UPDATES

AUGUST 2021

In August of 2018, Town of Marana Council made a unanimous decision to pursue the design and construction of a water treatment facility for each of the two impacted systems in Marana Water found to contain unregulated compounds (PFOS & 1,4-dioxane). These unregulated compounds currently do not have a Maximum Contaminant Level (MCL) applied by the EPA, but do have health advisories applicable. The decision was made to construct these water treatment facilities after evaluating several solutions, including blending alternatives and other water sources. Constructing water treatment facilities in each of the impacted systems was considered to be the most effective solution to providing safe, clean drinking water now and for future development. Construction of both Water Treatment Campuses (Picture Rocks – Continental Reserve Area, & Airline/Lambert – Saguaro Bloom Area) commenced in January 2020.

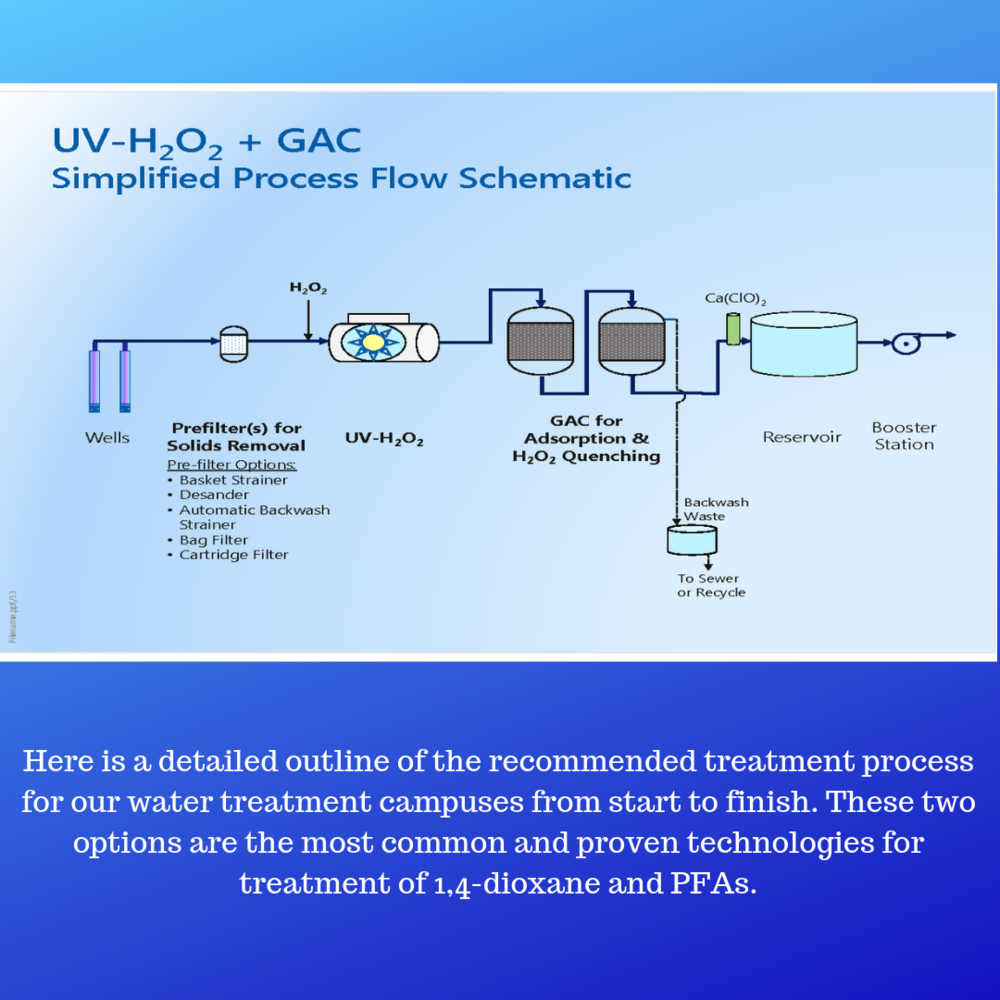

The below graphic illustrates an example of the treatment process that we are using at the water treatment campuses.

The Picture Rocks Water Treatment Campus and the Airline/Lambert Water Treatment Campus reached operational status on March 12th, 2021. Sampling results of the water being introduced into the respective systems from both treatment facilities continue to show successful removal of both of these non-regulated compounds (PFOS & 1,4-dioxane).

october/november 2020

In October and November installation of process piping and the installation of electrical instrumentation equipment commenced. The final site civil work, grading, site walls, and miscellaneous concrete slabs and sidewalk work activities were completed. Additionally, connectivity of automation and Supervisory Control and Data Acquisition (SCADA) networks began. SCADA is what will allow us to monitor and control the operation remotely.

Steel piping with Victaulic couplings, fittings, and valves are primarily being used for above grade piping at both project sites. Piping systems were ordered to length using a three dimensional model developed for each site based on as-builts of the previously installed underground piping and the design of the new process equipment. As the piping systems were being completed, tie-ins to the existing piping at both wells and backwash water connections were performed during planned outages overnight with which followed schedules planned hour by hour in order to reduce service disruptions to existing customers.

We have been very fortunate thus far that the majority of work and equipment has been installed as planned, but a few critical items have been unavoidably delayed as a result of various equipment suppliers being impacted by the COVID-19 pandemic. This included electrical equipment and mechanical equipment required for the well modifications which is one of the last steps to be completed at both sites. Modifications to the Saguaro Bloom well at the Airline/Lambert Water Treatment Campus is scheduled to is now scheduled to be completed December 2 – 12. Postcards were sent to customers requesting to conserve water during this time period.

Full process testing is now anticipated to be performed mid-December, pending final delivery of materials. Final approval from the Arizona Department of Environmental Quality (ADEQ) is required and we anticipate being fully operational in mid-January.

AUGUST/SEPTEMBER 2020

The last few months saw the continued arrival and installation of the treatment process equipment and electrical equipment. The UV vessels and its specific electrical components were installed at both sites. Additionally, GAC vessels were set in anticipation to connecting (piping) up to the new process system in the near future.

The GAC vessels were delivered and installed at both locations. Each vessel is paired with another vessel and has two sets which will function in a lead/lag mode. Each site has four vessels which are mechanically piped into a manifold for the various modes needed to run the GAC vessels. They were constructed offsite in California and transported on several semi low boy loads. Once onsite, temporary roads and grading to accommodate the low trailer loads were constructed to get the vessels and crane positioned to unload the vessels, manifolds, and pipe. It was a great job of planning, coordination, and communication between AqueosVets and the Archer Western team to pull it off without any issues.

Upcoming work in October and November will include the installation of process equipment, completion of mechanical piping, and startup/commissioning. A significant effort on instrumentation and control is planned to be completed as the sites will be fully automated. On the water supply side, modifications to increase pumping capacities and new electrical services to the existing well sites are planned to be completed as well. Startup of equipment and functional testing is anticipated to begin in October. Full operational testing and installation of GAC media are scheduled for November.”

Pictured here is the Airline Lambert treatment campus. The GAC tanks at this site are the four smaller tanks on the far left of the picture. The large building in the middle of the picture houses the UV equipment.

Overhead picture of the Picture Rocks Treatment Campus. The GAC vessels are the four tan smaller tanks in the lower middle of the picture.

JUNE/JULY 2020

June and July wrapped up the installation of underground process piping and the concrete slabs that house the process equipment. The UV buildings were dried-in (roof and doors) and interior conduits were installed awaiting delivery of the UV equipment. Equipment slabs and electrical gear were installed in July.

Also in July, the backwash tanks were delivered and installed at both locations. Each backwash tank is 17 feet in diameter and 22 feet tall, and has a volume of approximately 35,000 gallons. They were constructed offsite, in Tucson, and transported in the middle of the night with a police escort. What normally would have been a 30 minute drive took nearly 5 hours due to the oversize load and conflicts with more than 40 overhead structures (utilities, bridges and signage) along the route. Once onsite, temporary roads and grading to accommodate the low and wide load were constructed to get the tanks and two cranes positioned. There was great effort in planning, coordination, and communication between Smyth Industries of Tucson and the Archer Western team to pull it off without any issues.

Upcoming work in August and September will include the installation of process equipment and mechanical piping. A significant effort on instrumentation and control is also planned. On the water supply side, modifications to increase pumping capacities and new electrical services to the existing well sites are planned. Startup of equipment and functional testing is anticipated to begin in late September, with full operational testing scheduled for late October. Visit @MaranaWater on Instagram to view the latest construction update video.

April/May 2020

During the months of April and May our contractor, Archer Western, continued installing (at both locations) masonry walls, underground piping and electrical ductwork, along with performing concrete pour activities for footings and foundations to support and anchor the water treatment equipment and associated accessories.

Upcoming work for June and July will include structural steel and roof decking for the UV buildings, pouring tank ring walls for the backwash tanks, concrete placement for the sediment removal systems and slabs-on-grade for the granular activated carbon (GAC) vessels. The long-lead equipment items that had been previously ordered in December/January continue to be delivered and installed sequentially.

Check out this video where we walk through some of the construction being done at the sites. Check out the Marana Water Instagram page, @MaranaWater, for more photos/videos and updates.

february/march 2020

Archer Western has been hard at work readying the site. They have finished with the over excavation of the existing material and replaced it with properly compacted material to prevent settlement. They also did some trenching for footings and foundations for future construction. In addition, they have started installing the required underground piping and electrical ductwork. Many of the items and equipment needed for the treatment process require concrete footings and foundations to act as support and anchors. Archer Western has begun the process of pouring these foundations to get the site ready for equipment delivery.

The two pictures here show the progress at both construction sites. The one on the far left shows the concrete pour for the side wall for the UV building at the Airline/Lambert site while the one on the right shows the excavation work being done at the Pictures Rocks location.

The treatment process has several pieces of specialized equipment that needed to be ordered well in advance. These long-lead items were ordered in December and January and we expect them to be delivered and installed soon, and on schedule. Keep up with the construction by following our Instagram page @MaranaWater.

December 2019/January 2020

Our contractor, Archer Western, began mobilizing to both sites the week of December 9. This included setting up temporary offices, establishing utility connections, temporary fencing, delivering equipment and storage containers. Since then, the sites have been cleared, grubbed and portions of the existing walls have been demolished according to the design plans.

During the design process we determined that the soil conditions were not suitable to support the new facilities without modification. This required over excavation of the existing material and replacement with properly compacted material to prevent settlement. This excavation process started in December and will continue for a few more weeks. Next, we will begin installation of some of the underground piping, which will begin in late February. Check out the Marana Water Instagram page, @MaranaWater, for more photos and updates. Below shows work done during the week of January 27th. On the left is the Picture Rocks location and the right shows the excavation at the Airline/Lambert site.

october/november 2019

September through November saw all the final touches to the design plans and specifications for both treatment campuses. In October, final plans and specifications were submitted to the Arizona Department of Environmental Quality (ADEQ) for review. ADEQ reviews the project details to ensure that the proposed plans meet all applicable regulatory requirements, and once approved, will issue an “Approval to Construct” authorization from the State prior to construction.

In our August/September update, we talked about GMPs and the purchase of items that have a long lead time. We have issued GMP 1 and began the process of securing these items with our contractor, Archer Western, and equipment vendors. We have also reviewed and updated cost models for GMP 2 after additional reviews of the plans and bids from subcontractors and material suppliers Archer Western received. To ensure we got the best pricing available, we had multiple contractors bid on items like piping, bag fillers, granular activated carbon, steel tanks, sand separators, doors, masonry, asphalt and much more. While the overall cost of the project did increase over the original estimate of $15M to just over $16M, Town Council approved an increase in expenditure authority to cover these additional costs. Just like the $15M, we were able to secure a loan from WIFA to cover the expenses. Additionally, thanks to recently updated policy changes to the WIFA program, a portion of our second loan include forgivable principal, meaning the Town does not have to pay this portion back.

December is going to be a busy month for the two sites. We will issue a notice to proceed on GMP 2 on December 6, and the contractor will begin mobilizing as soon as December 4. You can expect to see construction equipment, offices, storage containers, temporary fencing, and other items on both sites soon. We are still on track for a Fall 2020 completion date. Be sure to check our the new Marana Water Instagram page @MaranaWater to get more updates and pictures throughout the project.

August/September 2019

The 90% plan submittal was received by Marana Water in the last week of August and review began immediately by all team members. This includes the careful review (see June/July update) of every detail included on over 330 drawings and over 1600 pages of specifications. Because the water treatment campuses will be constructed at existing facilities that must remain operational during construction, the design also incorporates additional components such as additional piping and valves to minimize service interruptions while connecting the new treatment systems to the existing facilities. In fact, most tie-ins on projects like these will take place at night so most customers won’t notice any change in service. These tie-ins, as well as start-up and commissioning, will follow plans called MOPOs (Maintenance of Plant Operations), to ensure that tie-ins and start-up goes smoothly. MOPOs are comprehensive plans developed in well advance of a specific task that focus on preparedness, safety, and proper execution when construction interfaces with an operational facility.

Because we are at a 90% completion of design, many of the treatment components and larger pieces of equipment have been identified based on performance requirements. This includes the ultraviolet treatment/advanced oxidation equipment (UV/AOP) for destruction of 1,4-dioxane, the vessels and media for treatment of PFAS, and electrical and control equipment. Because these are not typically “off-the-shelf” items and often take weeks or months to procure and manufacture, GMP 1is being issued solely to procure these long-lead items (see previous updates for discussion on GMPs). A second GMP will be issued for the balance of the project, including all other equipment, materials and the onsite construction. The construction schedule will be built to accommodate delivery and placement of these items upon arrival.

June/July 2019

During the past two months, the Marana Water team has been detailing out the conceptual designs presented in the preliminary design report we received in April/May. The team is working toward a 60% design completion, and this is where the majority of the design takes place. This process addresses every aspect of the design and operation of the water campuses.

What gets reviewed? Well, each part of the construction and design. Each requirement from the type of fill (dirt) needed, to electrical control panels and nuts and bolts used on the construction site. These items can be explicitly stated on the plans or are outlined in the technical specifications to be used on the project. Equipment manufacturers are included in these discussions to make sure equipment will meet the design requirements. Area is measured and verified to ensure delivery vehicles have appropriate room to enter and leave the site for operational needs. Structural engineering calculations and designs are done for pads that will support equipment and the walls on the site. There is a review of the impact the new sites will have on the surrounding area and confirmation that all safety requirements are met. Other aspects are verified like the hydraulic calculations, that they site layouts will allow for staff to access equipment for maintenance purposes, and the contractor provides a constructability review stating that it can be built as it is designed. The team even selects the paint colors.

Marana Water has reviewed the 60% design in late June and provided comments back to Carollo. Our contractor, Archer Western, has begun to put cost estimates together based on the 60% design. They will discuss with vendors to secure bids for equipment and labor, while Carollo incorporates the comments and continues work toward a 90% design. Both sites are scheduled to begin construction in Fall 2019 with start-up testing in late July/early August 2020. We anticipate both sites to be fully operational in September 2020.

April/May 2019

CONSTRUCTION PROCESS

During the past two months, our engineering consultant, Carollo Engineering, completed a draft preliminary design report (PDR). This report includes proposed site layouts, preliminary equipment sizing, and treatment process selection. The Marana Water team has reviewed the PDR and the overall project is moving toward 60% completed design. Additionally, as planned, in April interviews were conducted to select the construction manager for the project. After the competitive process, Archer Western Construction was selected as the most responsive and capable firm. Archer Western is a large construction firm with offices located throughout North America, and our team will be working out of the Phoenix office. They have completed several water treatment projects in the Tucson and Phoenix areas, and have experience working with Carollo Engineering. Finally, the contract for preconstruction services, which includes constructability review, value engineering, and cost modeling, is nearing completion. Constructability reviews allow the contractor to evaluate step-by-step construction methods necessary to build a facility alongside the design engineer, providing the opportunity for reduced costs. Value engineering is a term used to improve a product’s value, or the ratio of its function to its cost. Some examples would be a substitution of materials that meet the specific requirements, but are available at a reduced cost, or the use of a different type of pump that operates at a higher efficiency, which could in turn generate operational savings over its lifetime. Archer Western has begun working with Carollo and Marana Water to keep the project on schedule. Once the cost model is complete, it will be used to create the Guaranteed Maximum Price (GMP) process to get equipment that could take a long time to order and be delivered, ensuring these items are available for installation.

TREATMENT PROCESS

To the right is an example of the recommended treatment process that we will use at the water treatment campuses. You can click on the image to enlarge it. First, water is pumped from wells through a series of filtration units to remove sediment or solids that are sometimes found in groundwater. Next, the unregulated compounds treatment process begins with an ultraviolet advanced oxidation process using hydrogen peroxide (UV AOP - H2O2). This means that hydrogen peroxide goes into the water ahead of a UV light. Once this water mixed with hydrogen peroxide passes through the UV light, hydroxyl radicals are generated. These radicals react with and break down the 1,4-dioxane to create harmless molecules of carbon dioxide and hydrogen. After the UV AOP process, the water moves to vessels filled with granular activated carbon (GAC). These GAC filters will absorb the PFAs and any remaining hydrogen peroxide from the UA AOP process. Finally, the water will be disinfected using chlorine and pumped into the reservoir and then the main distribution system for our customers. These two processes together are the most common and proven technologies of treating for1,4-dioxane and PFAs.

February/March 2019

Construction process

The project is moving along during the February and March periods. Our engineering team, Carollo Engineering, continued with the preliminary design of the sites. While this continues, in mid-February, the Town began a two-step selection process to hire a Construction Manager who will work with the Town and Carollo to deliver the project. We are going to be using a Construction Manager at Risk method for the construction of the sites. The first step is for statements of qualifications to be submitted and reviewed by a selection committee made up of industry professionals. This was completed in early March. Upon review, we moved to the second step where the selection team will interview the highest ranking firms in mid-April.

The Construction Manager at Risk (CMAR) process is a collaborative project delivery method where the Owner (Marana Water) contracts a designer and a construction manager separately and they then work as a team to complete the project. Both the engineering designer and the contractor need to be engaged with a contract. We retained Carollo Engineering in January of 2019, and are in the middle of the process to secure a contractor. Typically, the Owner will select a Construction Manager when the engineering design is at approximately 30% completion to perform pre-construction services. These services include working directly with the Owner and the designer to perform constructability reviews, cost modeling, and value engineering during the design process.

There are many advantages to using a CMAR process for complex projects like this one. First, during the pre-construction phase, the Construction Manager, along with the Owner and the designer, can collectively identify potential opportunities to accelerate the project schedule. Some examples of this are identifying items that have a long lead time, or putting portions of the projects out to bid that are earliy in the project timeline. Secondly, the Construction manager will also be performing careful cost modelling of the project by obtaining bids and cost estimates for the project. The Construction Manager is required to deliver the project with a Guaranteed Maximum Price (GMP). Typically, when the project is at the 90% design completion phase, the Construction Manager will provide this GMP, which includes predetermined Owner allowances and contingencies. This is where the “at-risk” comes into play. Each bid packages has a GMP based on the efforts and due diligence of the Construction Manager during pre-construction. The Construction Manager is financially liable, or “at-risk,” should there be any necessary costs to complete construction above and beyond the GMP. This is another advantage, by providing cost security to the Owner.

Regulation

On February 14, the EPA released their much anticipated “PFAS Action Plan.” According to the EPA, the PFAS Action Plan:

Demonstrates the agency’s critical national leadership by providing both short-term solutions and long-term strategies to address this important issue

Provides a multi-media, multi-program, national research, and risk communication plan to address this emerging environmental challenge

Responds to the extensive public input the agency has received over the past year during the PFAS National Leadership Summit, multiple communication engagements, and through the public docket.

To read a summary of the EPA’s Action Plan for PFAS, click here.

January 2019

On January 22nd, the Water Infrastructure Finance Authority (AZWIFA) approved a loan to the Town of Marana for $15 million for the design and construction of two advanced water treatment facilities. Upon closure of the loan documents, the Marana Council approved the design engineering services contract for Carollo Engineering. Carollo will be working with the Town throughout the duration of the project, which includes final design, construction oversight, treatment plant start up, and post-construction activities. A design kick-off meeting took place the week of January 22nd with Marana Water staff. Carollo is a national engineering firm that specializes in water and wastewater infrastructure projects. The team working with the Town is from the local Tucson office.

AZWIFA is a governmental organization dedicated to protecting public health and promoting environmental quality through financial assistance for water and wastewater infrastructure. AZWIFA offers funding for drinkign water, wastewater, and stormwater projects designed to ensure safe, reliable drinking water and proper wastewater treatment. Over the last 25 years, AZWIFA as invested over $2 billion in Arizona communities. For more information, visit the AZWIFA website here.

December 2018

On December 12th, the Water Infrastructure Finance Authority of Arizona (AZWIFA) approved the offer of a $15 million loan to the Town of Marana to address the issue of unregulated compounds. The final loan agreement documents with AZWIFA will be brought to the Marana Town council most likely in January 2019 for final acceptance.

Marana Water has selected and is currently negotiating a contract with a design engineering firm to begin the process of design for the two advanced water treatment plants. Each water system (Picture Rocks and Airline/Lambert) will have a treatment plant designed and constructed to significantly reduce or remove the discovered unregulated compounds (PFAs and 1,4-Dioxane).

November 2018

Town of Marana has joined City of Tucson in a lawsuit filed Nov 8 in Pima County Superior Court as part of their ongoing effort to protect the public from any potential adverse health effects that could be caused by per- and polyfluoroalkyl substances (PFAs) that are present in portions of the groundwater supply.

October 2018

Marana Town Manager Jamsheed Mehta wrote a letter to Town Council responding to questions about interim water consumption as the Town prepares to build two operational treatment plants for the Airline/Lambert and Picture Rocks water systems.

Additionally, Arizona Department of Environmental Quality wrote a letter supporting Town of Marana’s efforts to address unregulated compounds in drinking water.

September 2018

Town Council approved Resolution No. 2018-091 on Tuesday, September 25 authorizing the creation of the Picture Rocks water treatment campus capital project and the Airline/Lambert water treatment campus capital projects. The resolution also authorizes the transfer of up to two million dollars in budgeted expenditure authority, and authorizes the application for a clean water state revolving fund loan from the Water Infrastructure Finance Authority of Arizona (WIFA) to fund the construction.

Town Council Presentation Slides

Marana Resolution No. 2018-091

View the Sept 25 Council presentation video.

August 2018

The Town of Marana Council made a unanimous decision on Tuesday, August 14, 2018 to pursue design and construction of a water treatment facility for each of the two impacted systems in Marana Water found to contain unregulated compounds. Additional information can be found at the links below.

The Town of Marana Water Department is the proud recipient of two awards from the AZWater Association.